A Practical Guide to Using Rough Top Conveyor Belts

The successful Application of rough top rubber conveyor belt systems is crucial for industries that handle packaged goods or items requiring a secure grip during transit. Unlike standard smooth-surfaced belts, these specialized belts are engineered with a textured, non-slip surface that significantly increases friction. This unique characteristic makes them the ideal solution for conveying materials on inclines or declines, where product stability is paramount. Understanding how and where to apply this technology can dramatically improve operational efficiency, reduce product damage, and enhance workplace safety. This guide will walk you through the key uses and benefits of this essential material handling component.

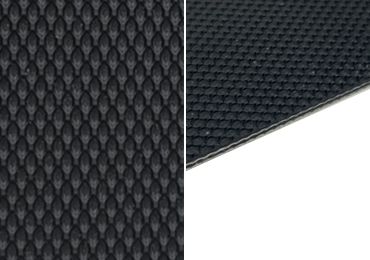

Understanding the Core Design and Functionality

The primary feature of a rough top rubber conveyor belt is its distinctive, textured surface. This pattern, which can vary from fine to coarse, is specifically designed to create an exceptional grip on the items it transports. The increased coefficient of friction ensures that boxes, bags, cartons, and other packaged goods remain stationary on the belt, even when moving up steep angles. This design is meticulously constructed from high-quality, durable materials that offer remarkable resistance to wear and tear. A robust and well-made rubber conveyor belt can withstand heavy loads and demanding operational environments, making it a reliable choice for industries ranging from logistics to manufacturing.

Key Industries and Common Applications

The versatility of the rough top rubber conveyor belt makes it indispensable across various sectors. In the packaging industry, it is used to move sealed boxes and bagged products along production lines without slippage. Logistics and distribution centers rely heavily on these belts for sorting systems and loading docks, where packages are often moved up inclined conveyors into trucks. Airport baggage handling is another critical application, as the belts securely transport luggage of all shapes and sizes through complex systems. Furthermore, in manufacturing settings like woodworking or electronics assembly, these belts gently but firmly move finished products or delicate components, preventing scratches and damage that could occur on a smoother surface.

Mastering Incline and Decline Conveying

One of the most significant challenges in material handling is moving items vertically. This is where the rough top rubber conveyor belt truly excels. For incline applications, the high-grip surface prevents gravity from causing products to slide back down, ensuring a consistent and uninterrupted flow of materials. This is essential for moving goods from a warehouse floor to a mezzanine level or feeding products into elevated machinery. Conversely, during decline conveying, the belt provides controlled movement, preventing items from accelerating and crashing into each other at the bottom. This control is vital for safely unloading materials from a higher level or gently transitioning them to another part of the production line, minimizing damage and maintaining order.

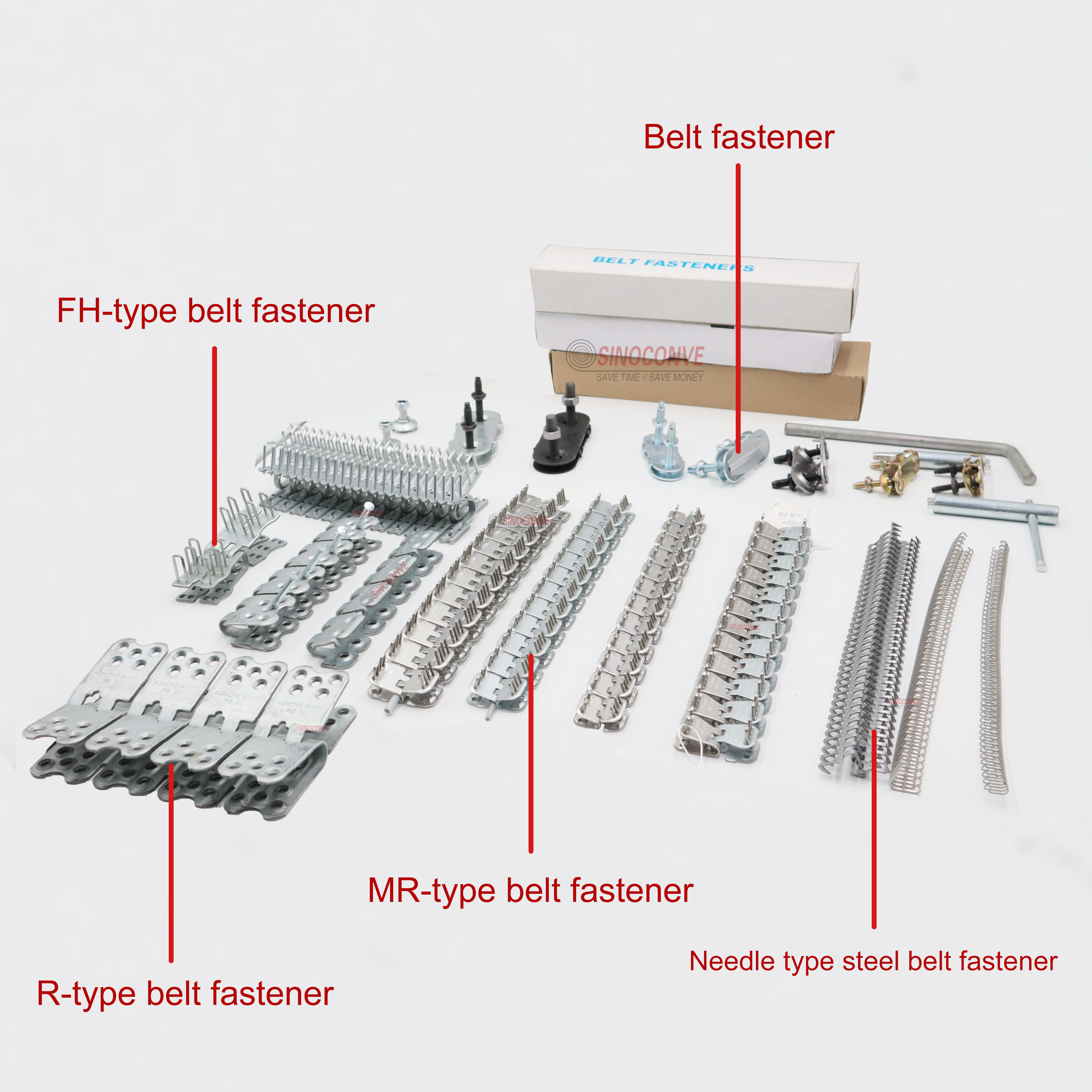

Installation and Maintenance Best Practices

To maximize the lifespan and performance of your conveyor system, proper installation and maintenance are key. When installing a new belt, ensure it is properly aligned and tensioned according to the manufacturer's specifications to prevent premature wear. Regular maintenance should include inspecting the belt surface for any signs of damage or excessive wear and tear. Thanks to its durable composition, the belt is often resistant to oils and grease, which simplifies cleaning. A simple wipe-down can often remove debris and maintain its gripping properties. Regularly checking the splice and tracking will also ensure the system runs smoothly, minimizing downtime and maximizing productivity for all your material handling needs.