Overcoming Common Challenges in Conveyor Belt Jointing Methods

In industrial settings, conveyor systems are vital for efficient material handling, but ensuring seamless operations often hinges on effective conveyor belt jointing methods. When belts wear out or need repairs, improper jointing can lead to downtime, safety hazards, and increased costs. This article explores the problems associated with traditional conveyor belt jointing methods and presents practical solutions, including innovative fasteners that can transform your maintenance routine.

Problems with Traditional Conveyor Belt Jointing Methods

One major issue with conventional conveyor belt jointing methods is the time-intensive nature of processes like cold vulcanization or hot splicing. For instance, rubber conveyor belt jointing methods using adhesives or heat require specialized equipment and skilled labor, often halting production for hours or even days. This downtime translates to significant financial losses, especially in high-volume operations. Additionally, these methods can weaken the belt's integrity over time, leading to frequent failures under heavy loads or abrasive conditions. Belt jointing methods that rely on mechanical means without proper support may also cause uneven tension, resulting in slippage, misalignment, or premature wear. Safety risks escalate when joints fail unexpectedly, posing dangers to workers and damaging goods. In environments with varying loads, such as mining or manufacturing, these challenges compound, making reliability a constant concern.

Solutions Through Advanced Belt Fasteners

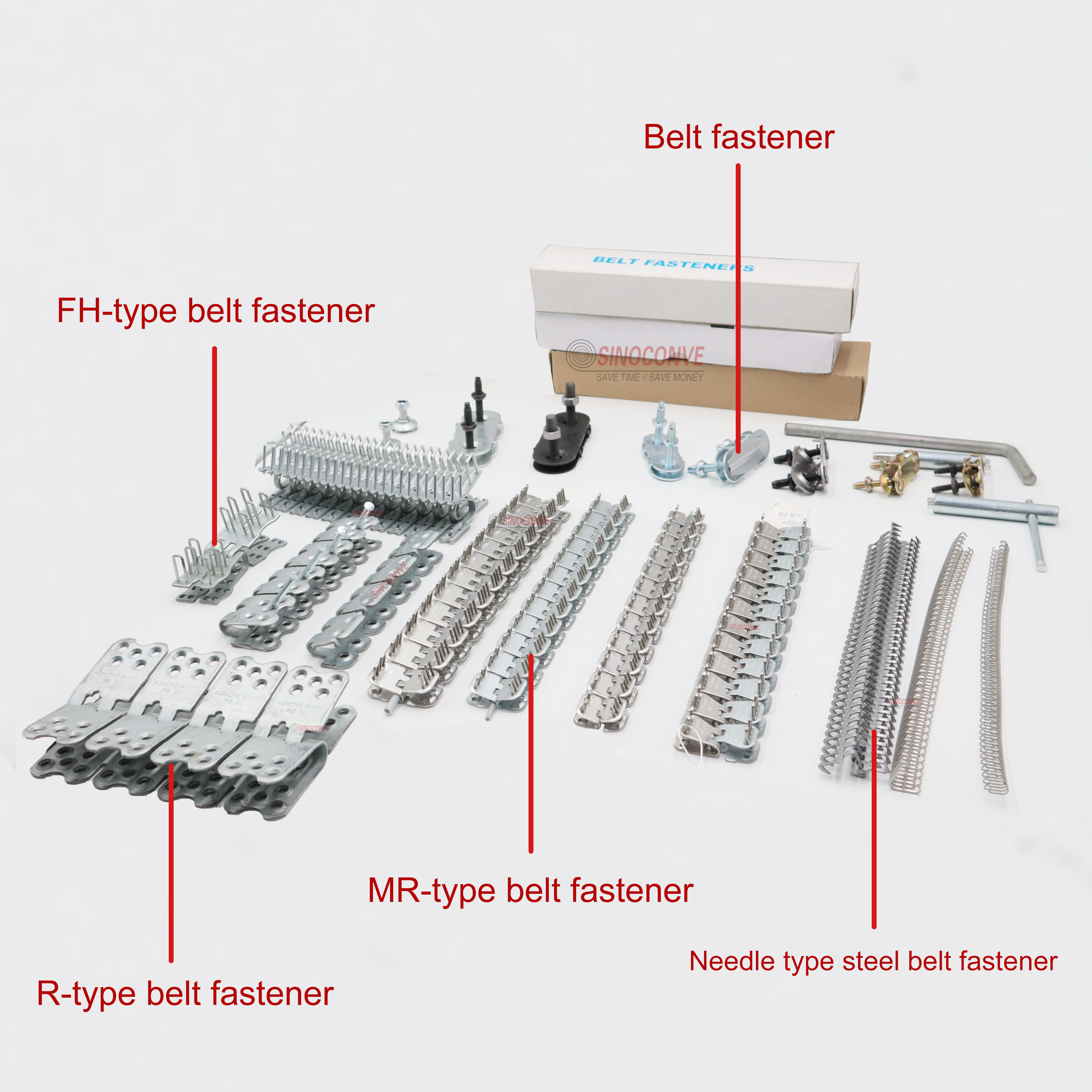

Fortunately, modern conveyor belt fastener options address these pain points by offering quick, durable, and versatile jointing solutions. For heavy-duty applications, the FH-type belt fastener provides exceptional tensile strength, allowing for rapid installation without the need for heat or chemicals. This method reduces downtime to mere minutes, ensuring minimal disruption. In medium-duty scenarios, the MR-type belt fastener strikes a perfect balance of flexibility and robustness, ideal for general-purpose conveyor systems where adaptability is key. These fasteners integrate seamlessly with rubber conveyor belt jointing methods, enhancing overall performance. For lighter loads, the R-type belt fastener excels in ease of use and longevity, preventing the slippage issues common in outdated belt jointing methods. Moreover, the needle type steel belt fastener offers precision for intricate setups, maintaining strength without bulk. By incorporating these conveyor belt fasteners, industries can achieve joints that withstand harsh conditions, extend belt life, and lower maintenance expenses.

Implementing Effective Conveyor Belt Jointing Strategies

To maximize the benefits of conveyor belt jointing methods, start by assessing your operational needs—consider load weight, belt material, and environmental factors. Pairing traditional rubber conveyor belt jointing methods with compatible fasteners like the FH or MR types can create hybrid solutions that combine the best of both worlds: the seamlessness of vulcanization with the speed of mechanical fastening. Training staff on proper installation techniques for belt jointing methods ensures consistent results, while regular inspections prevent minor issues from escalating. In practice, companies using conveyor belt fasteners report up to 50% reductions in repair times and significant cost savings. For specialized needs, the R-type or needle type steel belt fastener can be customized to fit unique conveyor configurations, promoting smoother material flow. Ultimately, shifting to these advanced conveyor belt jointing methods not only solves immediate problems but also future-proofs your operations against evolving industrial demands. By prioritizing reliable jointing, you safeguard productivity and safety in your material handling systems.