Not All PVC Conveyor Belts Are the Same: How to Match the Right Type to Your Workflow

Why the Structure of a PVC Conveyor Belt Matters

PVC conveyor belts are commonly used in clean, light-duty, and automated systems. But choosing the wrong type—whether it’s in the joint method, belt surface, or structural reinforcement—can lead to slippage, tracking issues, and premature wear. That’s why understanding the four primary structures of PVC belts is essential when designing or upgrading your material handling line.

Clipper Joint PVC Conveyor Belts: Easy Installation, Fast Replacement

Clipper joint PVC belts use a mechanical fastener (metal clipper) to join belt ends, making installation and maintenance exceptionally fast. This design is especially useful for systems that require frequent belt removal or quick part replacement.

Best for:

-

Temporary production lines

-

Environments with frequent belt maintenance

-

Manual packaging or sorting areas

Advantages:

-

No vulcanization needed

-

Easy to disassemble and reassemble

-

Minimal system downtime

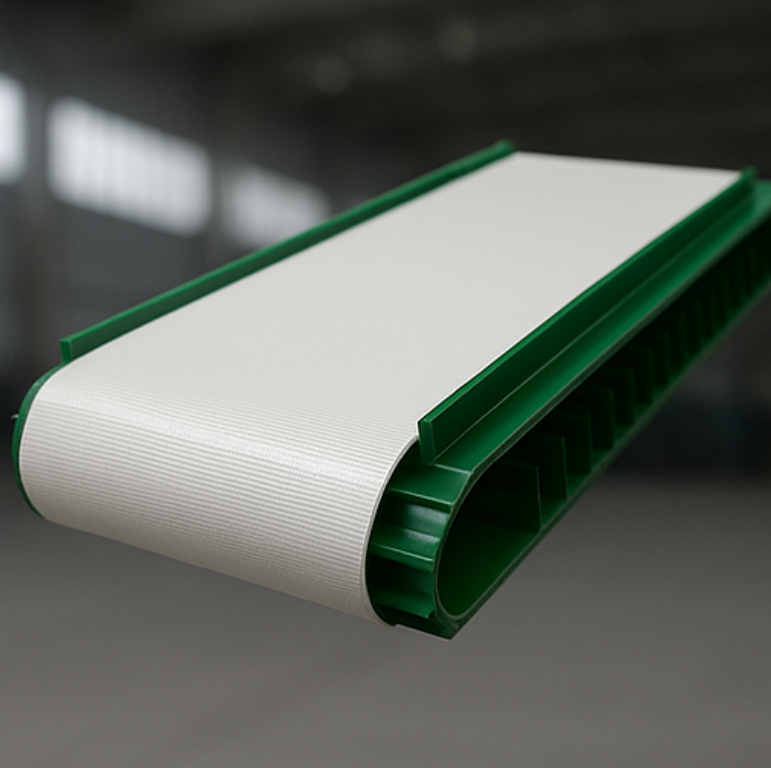

Flat PVC Conveyor Belts: Clean, Smooth, and Versatile

Flat PVC belts are the most common option for clean conveying. They feature a smooth surface with no cleats, guides, or structural reinforcements, making them ideal for food processing, pharmaceuticals, and electronics assembly lines.

Best for:

-

Food handling and packaging

-

Pharmaceutical transport

-

E-commerce and small parcel handling

Advantages:

-

FDA food-grade options available

-

Easy to clean and sanitize

-

Lightweight and energy-efficient

PVC Belts with Guide Strips: For Precise Tracking and Alignment

Guide-strip PVC belts include one or more V-shaped or rectangular strips welded under the belt. These strips run in grooves along the conveyor frame, ensuring accurate belt tracking and preventing lateral slippage.

Best for:

-

Automated systems with high accuracy demands

-

Multi-lane sorting or scanning systems

-

Narrow conveyors and compact machinery

Advantages:

-

Prevents belt misalignment

-

Suitable for high-speed conveyors

-

Reduces belt wear caused by off-track movement

Sidewall PVC Belts: Vertical Lifting with Minimal Footprint

Sidewall belts have raised barriers along the belt edges that hold materials in place during inclined or vertical transport. This structure enables effective conveying in space-constrained environments or for steep lifting angles.

Best for:

-

Inclined conveying systems

-

Space-optimized material handling

-

Agricultural, recycling, or packaging lines

Advantages:

-

Prevents material spillage on inclines

-

Increases load capacity per square meter

-

Reduces overall system footprint

How to Choose the Right PVC Belt for Your System

When selecting a PVC conveyor belt, consider the following:

| Criteria | Considerations |

|---|---|

| Installation Method | Do you need quick-change belts? → Clipper joint |

| Cleanliness Requirements | Is the product sensitive to contamination? → Flat PVC |

| Tracking Accuracy | Are you facing belt deviation issues? → Guide strip |

| Space & Elevation | Need to move materials upward or in tight space? → Sidewall |

Always match belt type to the specific demands of your equipment and material characteristics. Poor matching can lead to unnecessary wear, increased energy use, or process inefficiencies.

Why Choose Sinoconve for PVC Conveyor Belts?

At Sinoconve, we manufacture all four major types of PVC conveyor belts in-house with customizable options, including:

-

Color (white, green, blue), thickness, and surface texture

-

FDA-compliant and anti-static coatings

-

Custom cleats, sidewalls, and welded guides

-

OEM support and global delivery for production lines of all sizes

Our engineering team helps customers match the right belt to their industry and application—whether it’s food, e-commerce, logistics, or packaging.

Ready to Upgrade Your Conveyor System?

No matter your industry, the right PVC conveyor belt can improve product flow, reduce downtime, and increase output quality. With the right structure and guidance, even a small upgrade can yield big operational gains.

📩 Explore our PVC belt range at Sinoconve's homepage or request a quote directly on our contact page.