Oil Resistant Conveyor Belts: Reliable Performance for Greasy and Oily Environments

Why Oil Resistance Matters in Conveyor Systems

Many bulk materials contain or generate fats, oils, grease, solvents, or hydrocarbon residues that can degrade standard rubber belts. Exposure to oils causes swelling, surface cracking, ply separation, and belt hardening—leading to unplanned shutdowns and costly replacement.

An oil resistant conveyor belt is specially engineered with non-polar rubber compounds (such as Nitrile Rubber / NBR) that resist absorption, maintain flexibility, and preserve tensile strength even under prolonged oil contact.

Key Features of Oil-Resistant Belts

-

Oil-Repellent Rubber Compounds

Designed to prevent oil absorption that would otherwise cause rubber to soften, swell, or deform. -

High Adhesion and Anti-Delamination

Strong bonding between rubber layers and inner fabric prevents peeling or blistering under continuous exposure. -

Durability in Repeated Contact

Withstands repeated contact with grease, fats, and petroleum-based fluids without loss of function. -

Retains Flexibility

Maintains structural integrity during bending, troughing, and loading over rollers—even in slick conditions. -

Optional Heat + Oil Resistance

For use in environments where oil and moderate heat (up to 120°C) are present simultaneously.

Common Applications for Oil-Resistant Belts

Oil-resistant conveyor belts are critical in systems that move processed materials, scraps, or by-products containing oils or chemical fluids:

Recycling Plants

-

Plastic film and packaging contaminated with oil

-

Shredded electronics or car parts with residual lubricants

-

Used cooking oil containers or rubber compounds

Agriculture and Biomass

-

Oilseed cakes (soybean, sunflower, rapeseed meal)

-

Biomass pellets and organic waste

-

Animal feed with high fat/oil content

Food Processing & Slaughterhouses

-

Meat trimmings, skin, fat residues

-

Oily or fried food products on packaging or handling lines

-

Conveyorized cook/chill systems requiring washable belts

Rubber and Chemical Industry

-

Conveying uncured rubber, polymer sheets, or oil-impregnated components

-

Powder coating lines where release agents are present

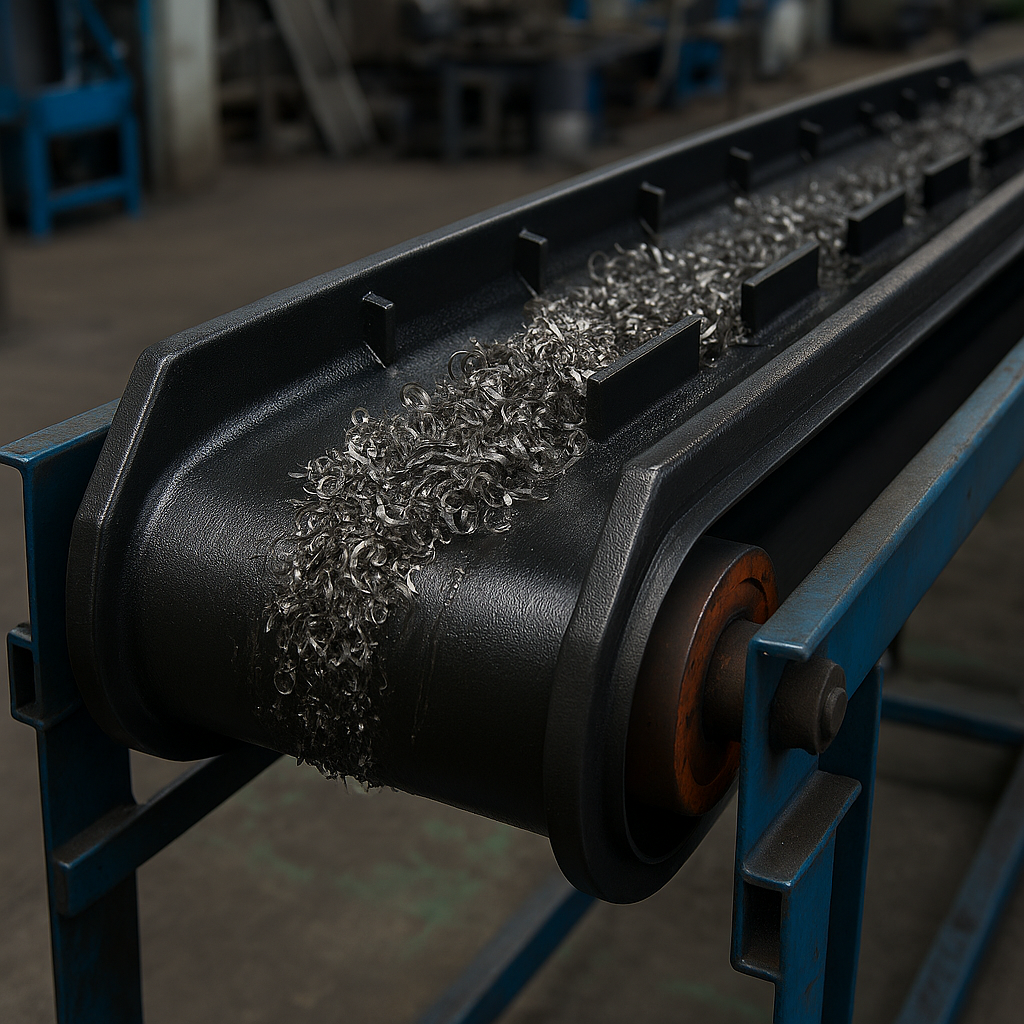

Metalworking & Auto Plants

-

Metal chips or parts with residual cutting oils

-

Lubricated components in engine or transmission lines

Material Grades for Oil-Resistance

Sinoconve offers oil-resistant belts with cover grades tailored to oil severity:

| Grade | Description | Best For |

|---|---|---|

| OR-G (General Purpose) | Moderate oil resistance, economical | Food-grade oils, mild greases |

| OR-H (Heavy-Duty / NBR-based) | Strong resistance to mineral/petroleum oils | Auto parts, metal shavings, synthetic lubricants |

| OR-FR (Oil + Fire Resistant) | Combined resistance for hot/oily environments | Recycling, foundries, waste fuel handling |

| OR-FOOD | Food-safe, oil-resistant PVC or PU | Edible oils, meat handling, FDA environments |

Each belt is tested for volume change (%) after immersion in oil, tensile retention, and flex cycle durability.

How to Choose the Right Oil-Resistant Belt

When selecting an oil-resistant belt, consider:

| Factor | What to Look For |

|---|---|

| Type of Oil | Animal fats, vegetable oils, lubricants, synthetic or mineral oils? Each reacts differently. |

| Contact Mode | Splashing, immersion, fine mist, or soaked material? Higher exposure needs higher OR grade. |

| Heat Presence | If oils are hot (70–120°C), choose OR + Heat Resistant compound. |

| Food Safety | For food contact zones, select non-toxic, FDA-approved covers (PVC or PU). |

| Cleaning Requirements | Frequent washing? Smooth surface belts improve hygiene and reduce residue. |

| Belt Base Material | Rubber (NBR) for durability; PVC/PU for hygiene and lighter loads. |

Note: Belt jointing (vulcanized vs mechanical), cleats, and sidewalls must also be oil-compatible.

Why Choose Sinoconve’s Oil-Resistant Conveyor Belts?

Sinoconve manufactures oil-resistant belts with:

-

NBR-blended rubber covers for OR-G, OR-H, OR-FR grades

-

PVC/PU oil-resistant belts for cleanroom and food processing

-

Custom widths, cleats, and sidewalls on request

-

Anti-static and flame-retardant options for special use cases

-

Global shipping + OEM support with MOQ flexibility

-

ISO 9001, SGS, and food-grade (on request) certifications

Whether you're handling oily biomass, greasy food products, or lubricant-soaked recyclables—our belts are built to resist oil damage and deliver consistent performance.

Get the Belt That Stands Up to Grease, Fat, and Oil

Standard belts won't survive in oily conditions. Invest in a conveyor belt that's made to resist chemical attack, protect your equipment, and run longer between changes.

📩 If you are looking for this type of conveyor belt or want to learn more, please visit our product page or contact us directly. We will get back to you within 24 hours.