Understanding Logistics Conveyor Belts: Core Functionality and Design

In the dynamic world of supply chain management, the logistics conveyor belt stands out as a foundational element for efficient material handling. This essential component streamlines the movement of goods from one point to another, reducing manual labor and minimizing errors. Unlike traditional manual transport methods, which rely on human effort and can lead to inconsistencies, a well-designed logistics conveyor belt ensures continuous flow and scalability. For instance, in high-volume distribution centers, these belts operate around the clock, adapting to varying loads and speeds to maintain productivity. The integration of advanced materials, such as PVC, further enhances their reliability, making them a preferred choice over older rubber-based systems that degrade faster under constant use.

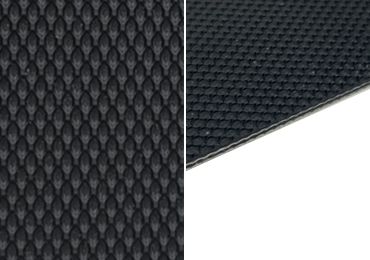

Warehouse Conveyor Belt Variations: Comparing Textured vs. Smooth Surfaces

When delving into specific applications, the warehouse conveyor belt emerges as a specialized subset of logistics conveyor belts, tailored for indoor storage and sorting environments. A key distinction lies in surface design; smooth belts facilitate quick, frictionless movement for lightweight items like electronics, contrasting sharply with textured variants that prioritize grip for bulkier or irregular loads. Take the Golf PVC Conveyor Belt, for example—its innovative golf ball-like texture provides superior traction, drastically reducing slippage compared to standard smooth belts, which can cause jams and downtime in busy warehouses. This texture not only boosts safety by preventing product displacement but also extends belt lifespan through even wear distribution, outperforming flat surfaces that often require frequent replacements. In contrast, while smooth belts excel in high-speed scenarios with minimal handling needs, they fall short in stability for diverse cargo types, highlighting the textured warehouse conveyor belt's edge in versatility.

Performance Comparison: Durability and Efficiency in Real-World Settings

Comparing logistics conveyor belts across broader metrics reveals stark differences in durability and operational efficiency. Traditional belts, often made from basic synthetics, succumb to environmental stresses like abrasion and chemicals, leading to higher maintenance costs and interruptions. Conversely, modern options like the Golf PVC Conveyor Belt, with its high-quality PVC construction, resist wear far better, offering up to twice the service life in demanding conditions. This resilience is particularly evident in logistics scenarios involving heavy pallets versus delicate packaging in warehouses; textured belts handle both with precision, minimizing damage rates that plague smoother alternatives. Efficiency-wise, the logistics conveyor belt's ability to integrate with automation systems outshines manual alternatives, cutting energy use by integrating seamless speed controls. In warehouse conveyor belt setups, the textured design further amplifies this by ensuring consistent throughput, even with mixed inventory, whereas non-textured belts may necessitate additional stabilizers, increasing complexity and expense.

Choosing the Right Belt: Balancing Cost, Maintenance, and Scalability

Ultimately, selecting between logistics conveyor belts and their warehouse-specific counterparts involves weighing cost against long-term benefits. Basic models might appear economical upfront but incur hidden expenses through frequent repairs and reduced output, in stark contrast to premium textured belts like the Golf PVC Conveyor Belt, which, though initially pricier, deliver ROI through lower downtime and enhanced grip for varied applications. Maintenance routines also differ: smooth logistics conveyor belts require regular lubrication to combat friction buildup, while textured warehouse conveyor belts self-regulate slippage, simplifying upkeep. For scalability, the logistics conveyor belt's modular design allows easy expansion in growing operations, outperforming rigid warehouse systems that struggle with volume spikes. This comparison underscores how investing in a durable, grippy solution not only optimizes workflow but also future-proofs infrastructure against evolving industry demands, ensuring both form and function in material handling.