Tired of Belt Failures? What to Know Before Buying a Rubber Conveyor Belt

What Exactly Is a Rubber Conveyor Belt?

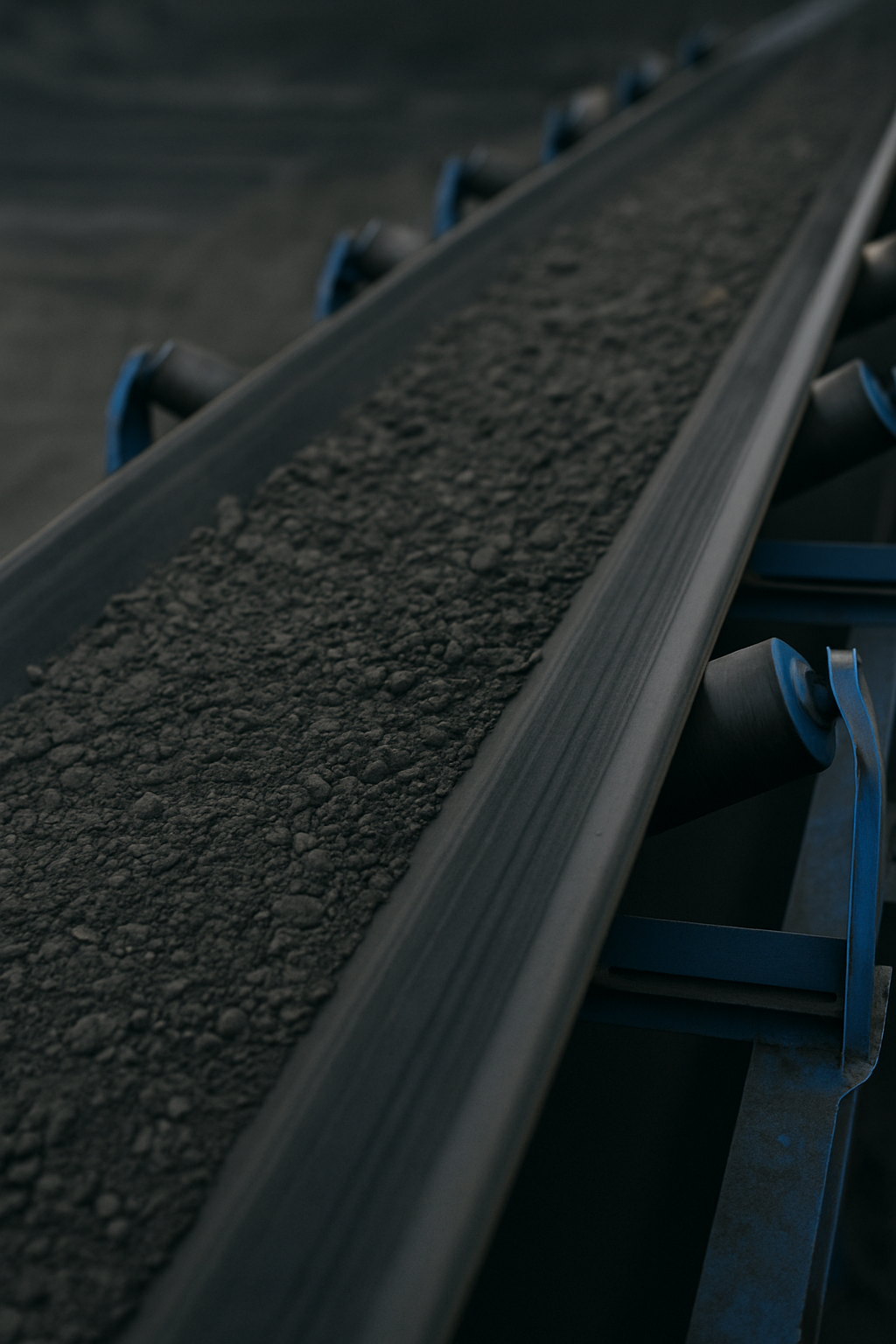

A rubber conveyor belt is a multi-layered system consisting of fabric reinforcements (usually polyester or nylon) and outer rubber covers. The rubber component is what gives the belt its resistance to wear, impact, heat, or oils—depending on the application. Choosing the right rubber for conveyor belts is the key to system longevity.

Common rubber types include SBR, NBR, CR, and EPDM, each optimized for specific environmental challenges like abrasion, oil, fire, or heat.

Know Your Rubber: Not All Compounds Are Equal

Each type of rubber compound brings unique strengths to industrial use:

| Rubber Type | Properties | Ideal Applications |

|---|---|---|

| SBR | High abrasion resistance | Quarrying, mining, cement |

| NBR | Strong oil and chemical resistance | Recycling, auto parts, oily bulk materials |

| CR (Neoprene) | Fire-retardant and weather resistant | Underground mining, energy sector |

| EPDM | Heat resistant up to 200°C | Asphalt, foundries, thermal plants |

| Natural Rubber | High tensile and flexibility | General conveying, light-duty loads |

Choosing the wrong rubber can mean rapid cracking, swelling, or even system shutdown.

How the Right Rubber Belt Improves Performance

Investing in quality rubber conveyor belts brings multiple operational benefits:

-

Longer Wear Life – Reduces downtime and replacement costs

-

Specialized Resistance – Handles oil, heat, fire, and chemicals without degradation

-

Improved Safety – Fire-retardant rubber minimizes risks in coal and power industries

-

Consistent Grip – Maintains performance under curves, incline, or impact zones

Rubber belts also support tailored cover thickness and multi-ply strength for custom load conditions.

Where Rubber Conveyor Belts Deliver the Most Value

Rubber conveyor belts are indispensable in:

-

Mining & Aggregates – Heavy-duty materials like ore, coal, stone

-

Cement Production – High friction zones and dust-heavy environments

-

Ports & Terminals – Handles bulk loading with oil and moisture exposure

-

Recycling Facilities – Needs resistance to sharp, oily, or mixed debris

-

Agricultural Conveyor Systems – For grains, fertilizers, biomass

Each scenario requires specific rubber properties—so working with a material-matched belt is essential.

Choosing the Right Belt: Practical Tips

To avoid costly belt failures, consider:

-

Material Properties – Oil, moisture, chemical, or high-heat exposure

-

Belt Strength & EP Rating – Load weight and tension requirements

-

Cover Thickness – Affects lifespan and impact resistance

-

Fire Safety Compliance – Needed for underground, energy, or tunnel operations

-

Supplier Expertise – Source from a factory that can validate compound and test data

It’s not just about price—it’s about the total cost of ownership and operational reliability.

Why Industrial Clients Choose Sinoconve

Sinoconve delivers rubber conveyor belts with:

-

Certified rubber compounds for each application

-

Tensile ratings from EP100 to EP500 and above

-

Custom options: Chevron, sidewall, cleated, oil- and fire-resistant

-

Fast global shipping and OEM support with low minimums

-

Standards compliance: ISO, DIN, RMA, SANS, SGS

Used in over 117 countries, our belts power critical systems in mining, cement, ports, and energy.

Get the Right Rubber Belt—Built for Your Workload

Don’t let the wrong rubber cost you more. Whether you’re running heavy-load mining lines or oil-sensitive recycling systems, the material inside the belt determines your success.

To get expert help choosing the right belt, visit our homepage or reach out through our contact page.