-- High strength

-- High resistant to abrasion

-- Low elongation

-- Resistant to impact

-- Suitable for long distance,large loading capacity and high speed transportation

SINOCONVE conveyor beltare designed to the highest standards ,to transport all types of bulk material,including mining, stone and earth handling , building industries,recycling, steel processing , wood, paper and pulp.

-- High strength

-- High resistant to abrasion

-- Low elongation

-- Resistant to impact

-- Suitable for long distance,large loading capacity and high speed transportation

GB/T 7984 DIN 22102

JISK 6322 AS 1332-2000

SANS 1173:2005 BS 490

|

Cover Rubber grade

|

8MPA,10MPA,12MPA,15MPA

18MPA,20MPA,24MPA,26MPA

|

|

DIN-X,Y,W

RMA-1,RMA-2

N17,M24

|

||

|

Belt width (mm)

|

500,600.650,700,800,1000,1200

1400,1500,1800,2000,2200,2500

|

|

18",20",24",30",36",40",42"

48",60",72",78",86",94"

|

||

|

Tensile strength

|

EP315/3,EP400/3,EP500/3,EP600/3

EP400/4,EP500/4,EP600/4

EP500/5,EP1000/5,EP1250/5

EP600/6,EP1200/6

|

|

330PIW, 440PIW

|

||

|

Top+Bottom thickness

|

3+1.5, 4+2, 4+1.5, 4+3, 5+1.5,

|

|

3/16"+1/16", 1/4"+1/16"

|

||

|

Belt thickness

|

3mm,4mm,5mm,6mm,7mm,8mm,9mm,10mm,12mm,15mm,20mm,25mm

|

|

|

||

|

Belt length

|

10m,20m,50m,100m,200m,250m,300m,500m

|

|

|

||

|

Belt edge type

|

moulded(sealed) edge or cut edge

|

|

|

||

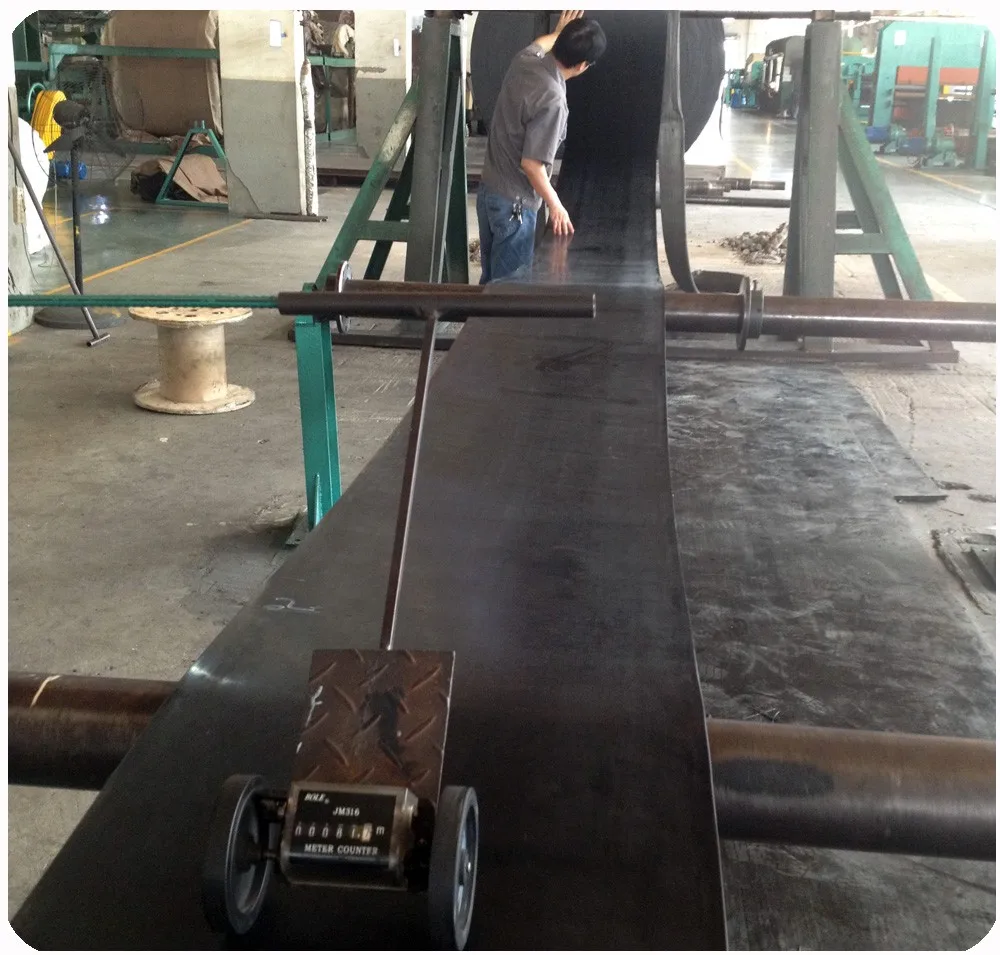

Step 1: Raw material inspection

Step 2: Advance equipment to guarantee quality from the details

4 rollers celender machine is able to stick rubber on both side of the fabric in one time.This can reduce the strength loss of the rubber during the process.

The forming tension is even between different plies,which can avoid wrinkled fabric and guarantee an even thickness of belt core.

We have an inspection team to inspect the surface and dimension of each conveyor belt. If any problem on belt surface, we will repair at once in our factory.

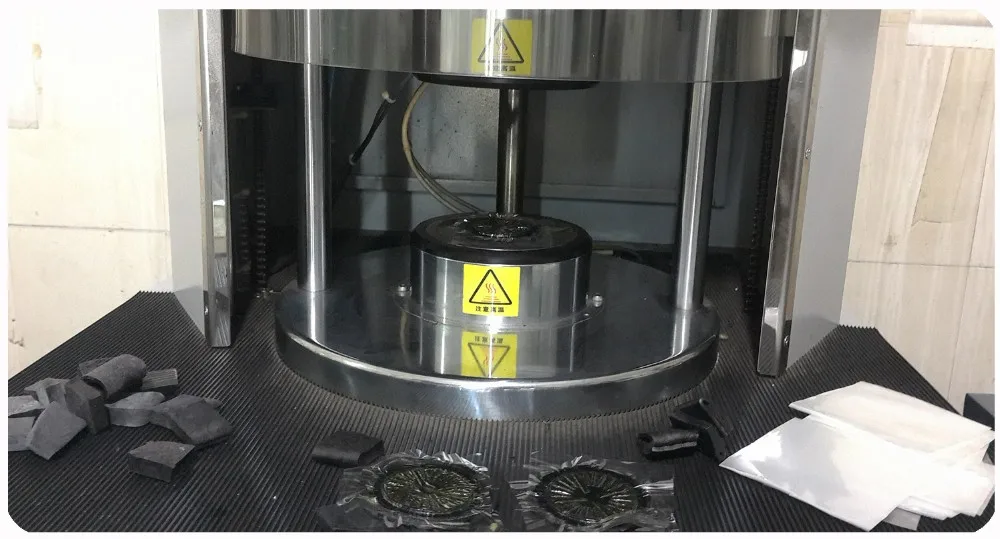

We have a lab to test all raw materials and rubber compound.For each roll of conveyor belt,the lab will test the following features, and issue Quality Test Report.

Yes, we mainly produce Rubber conveyor belts and Rubber v belts over 20 years.

1)3--5 days for sample

2)15--20 days for mass production. If urgent,we have green channel

1)T/T or L/C through bank account

2)Select Alibaba Trade Assurance Service

1)Inner is packed on round rubber core with 30cm diameter and 12cmx12cm square hole

2)Outer is packed with one ply water-proof PP fabric

We are committed to providing you with better products and services. Welcome to browse more content for details